Machine controllers have to fit into an overall system and exchange data with higher and subordinate levels. The range of communication protocols involved here is large. It is therefore necessary for controllers to speak several languages. The M1 controller system from Bachmann electronic is ideally suited for this: All important communication protocols are supported.

The higher-level control performs several functions. For one, it acquires data and compares it with the specified values. For another, it performs control tasks in all areas. The intermediate storage of data is particularly important for the communication with the control level since the control system calls up the data as required. It is therefore particularly important that all changes are provided with the correct time stamp.

The decentralization of control tasks through the spatial distribution of input/output terminals or intelligent drive amplifiers connected to a central controller is standard practice today.

Hard real-time for the field level

The connection of automation components via fieldbuses plays an important role in communication with the field level. The decentralization of control tasks through the spatial distribution of input/output terminals or intelligent drive amplifiers connected to a central controller is standard practice today. The basis for a functioning system here requires hard real-time and a reliable connection. The real-time requirement is not so definitive in the field of machine visualization: Although the user wants a fast response to his operator inputs here, a certain degree of delay is nevertheless permissible. Only when working on the setting up of a machine, such as the exact specification of clamp positions in an injection molding machine in inching applications, is hard real-time also indispensable even for machine visualizations.

Powerful fieldbuses as a success factor

A few years ago the term ‘distributed automation’ also involved more extensive concepts. In order to save costs, the plan was for an automation system to be implemented with a network of small microcontrollers that were limited in performance. This would therefore eliminate the need for a central powerful and thus more expensive controller. However this concept did not become established. The benefits of a central CPU were more significant on account of the advancements made, particularly through high-speed, Ethernet based fieldbuses.

Unified representation as a basis

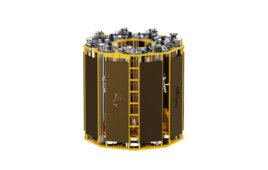

The M1 controller system from Bachmann is ideally suited for use in automation systems: Its core tasks, i.e. the open-loop and closed-loop control of the process, do not depend on the communication protocol in use. The UFB (unified fieldbus) representation enables the application program to access the cyclical data of a fieldbus in exactly the same way as with local I/O modules. If a fieldbus is replaced by another one, an adaption of the application software is normally not required.

Minimum effort, maximum customer benefit

The selection of the protocol for the control level is normally part of the specification of the end customer and is therefore modified considerably more frequently than a fieldbus. As the communication is configured and started as a user-defined software module, it is only necessary to map the process data (SVI variables) involved to the information objects of the relevant standard. This means that the required data points with the names of the SVI variables are entered in a CSV file. The logic operations of the application stay the same. This means that the user can respond quickly to customer requirements by simply changing the configuration without having to carry out extensive testing.

Bachmann Electronic

www.bachmann.com

Filed Under: News